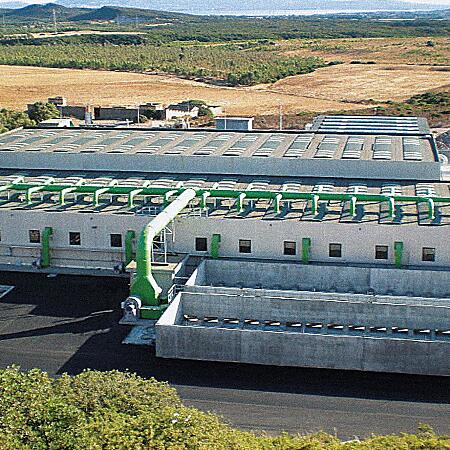

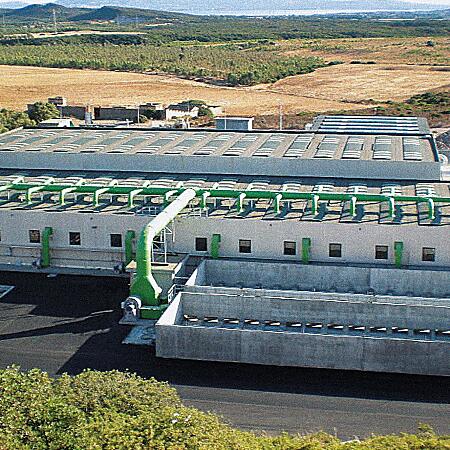

MBT Plant Carbonia

Carbonia/Sardinia

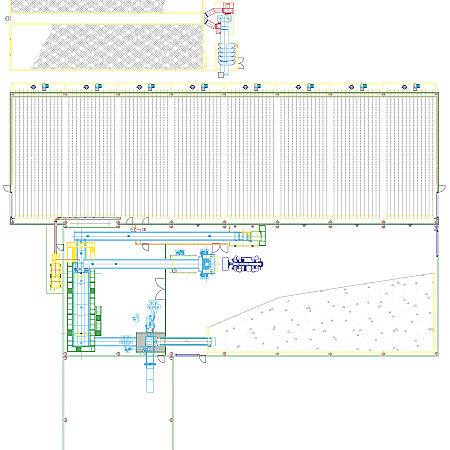

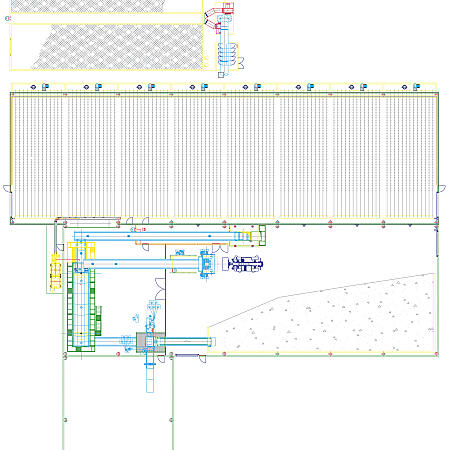

This municipal waste treatment plant, located in Sardinia and owned by the Municipality of Carbonia, has been designed to stabilise the organic fraction and to bale the components having a higher heating value separately. The plant consists of three lines:

• Mechanical treatment to sort the organic fraction and bale the combustible waste;

• Biological treatment to stabilise the organic fraction;

• Biofiltration of the process odours.

A slow-speed shredder is used to reduce the particle size of bulky waste and to open the bags containing the waste. After shredding, the waste is processed by a rotary screen, which sorts two fractions based on their particle size. The larger sized fraction, containing materials with higher heating value, is processed by a baler, while the organic fraction, after sorting of ferrous metals, is sent to the biological treatment area. The continuous channel baler has an automatic bale tying system and a by-pass conveyor that is used when baling is not required. The biological treatment line is based on a static pile composting system placed on an aerated platform. Eight fans are used to blow process air into the composting pile through an air distribution system integrated in the platform construction. After composting, the stabilised material is disposed at a sanitary landfill, where the emission of greenhouse gas is much less than in the case of untreated municipal waste. The plant is provided with a well sized odour control system that uses the biofiltration process. Two centrifugal fans, that process the exhaust air from the waste treatment plant, are installed in parallel upstream the biofilter.

System description: Sorting, baling and composting

Waste processed: Mixed municipal waste

Plant capacity: 48,400 t/year